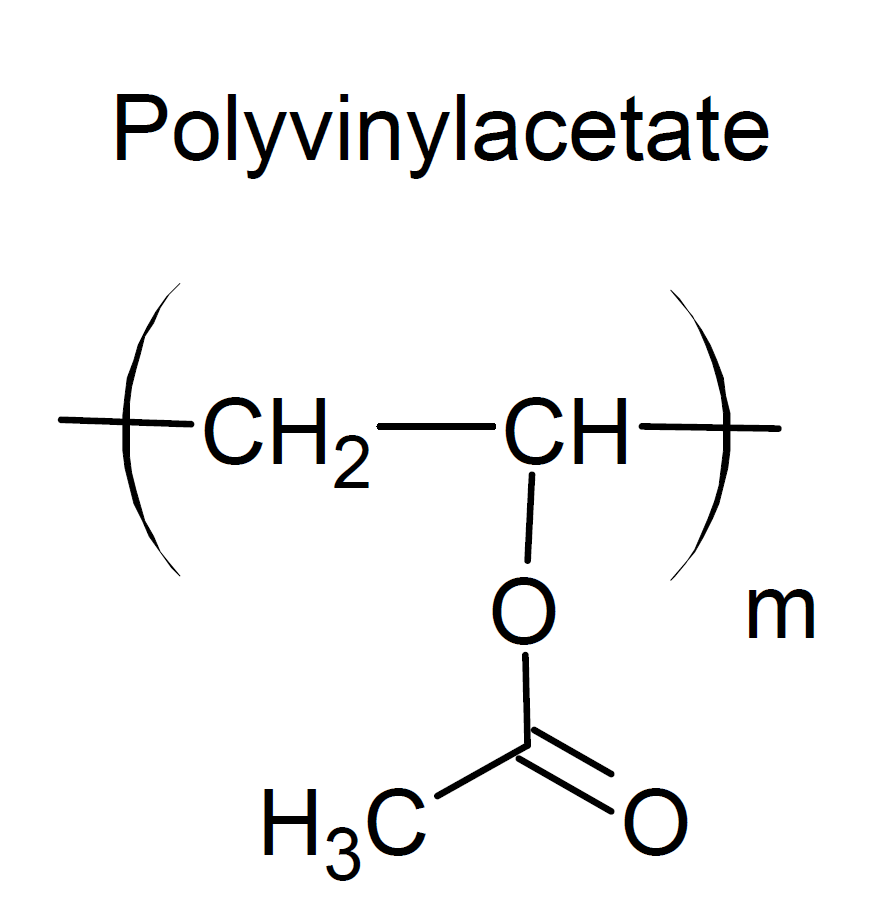

Polyvinylacetate (PVAC, PVA)

Properties and Applications

Polyvinyl acetate (PVAc, PVA) is an atactic, highly branched, and noncrystalline thermoplastic, prepared by conventional free-radical polymerization. It has good resistance to UV and oxidation, but is rather brittle below its Tg (ca. 35°C) and very sticky above it. PVAc emulsions are produced on a very large scale.1 They are inexpensive and possess good adhesion to many porous substrates, but are not effective on non-porous surfaces. They are one of the main ingredients of water based glues, commonly referred to as wood glue, carpenter's glue, Elmer's glue (USA), or white glue.

One of the most important uses of PVA adhesives is in the packaging industry. It is used as an inexpensive, low-toxic, and no odor adhesive to bond and seal high energy surfaces such as paper, corrugated carton, cotton, and wood, to name only a few. It is often preferred over other types of adhesives because of its low cost, good stability to light, and its resistance to unappealing yellowing. The polymer finds additional uses as a plasticizer and thickener for paints, textile finishes, plastics, cement, and chewing gum.1 PVAc is noticeably cheaper than acrylic resins (approximately half the cost) and is therefore often added to acrylic latex paints to lower cost. However, the best exterior water-based paints are 100 percent acrylic due to elasticity and other factors. Because of its water sensitivity, (unmodified) polyvinyl acetate is generally viewed as inappropriate for exterior uses.

Manufacturers & Distributors

Companies |

Brands |